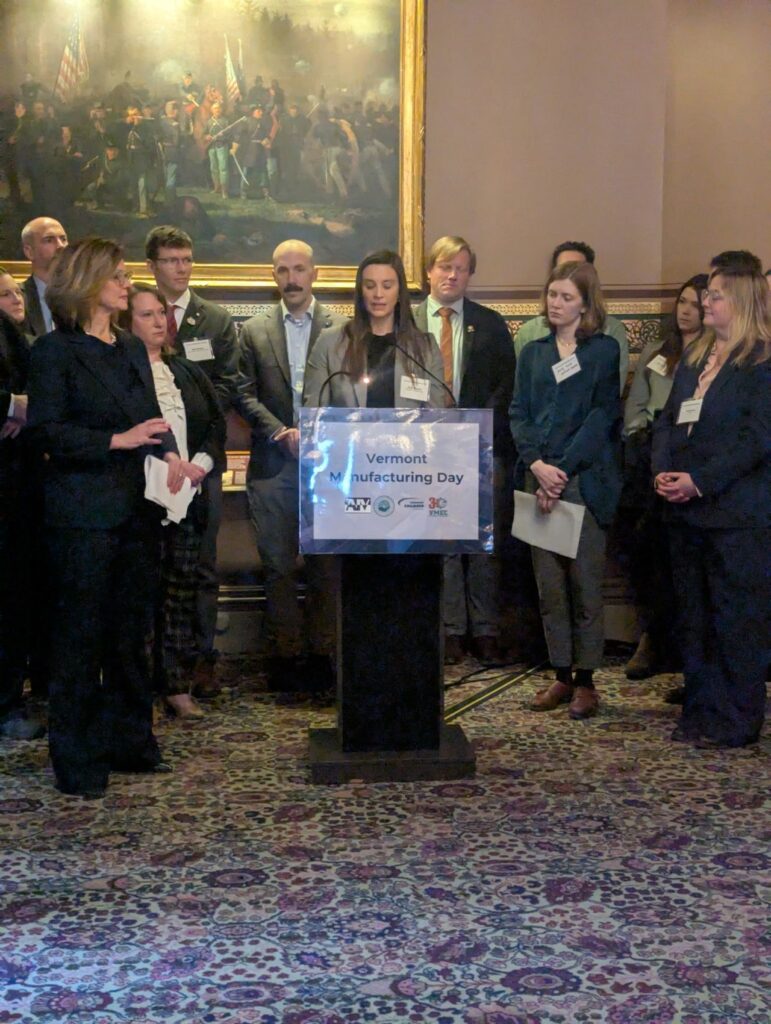

Testimony provided to a Joint Hearing of the Vermont House Commerce and Senate Economic Development committees on April 2, 2025. View recording here.

Legislators, thank you for the opportunity to speak with you today, and thank you to the organizers for creating this forum. My name is Diane Abruzzini Riggs, I am a co-founder of Rigorous Technology, a robotics company based in Williston, VT. We design and build robotic equipment for manufacturers, helping reduce repetitive, strenuous tasks. As a manufacturer that also serves other manufacturers, we have a unique view into the challenges and opportunities Vermont businesses are navigating.

Manufacturing Rooted in Vermont’s Maker Culture

We work with companies that build great products, a tradition rooted in the State’s maker culture. Vermont is home to household names like Cabot and Ben & Jerry’s. Others firms, like Hazelett and Chroma, are global leaders in high-tech niches.

Many are national role models in sustainability and employee ownership, sharing best practices through organizations like VBSR and serving as leaders in the B Corp and ESOP movements. These companies are productive, values-driven, and rooted in community, not to mention employers of 27,000 team members (down from nearly double that in 2001)1.

Manufacturing offers unparalleled upward mobility. The sector provides entry-level roles and long-term career paths in operations, engineering, sales, finance, IT, and more. I’ve met CEOs who got started on the plant floor, and those who carry on 5th generation family legacies.

Today, we are in the middle of a workforce crisis, and Vermont may feel it more acutely than neighboring states. I hear stories like this every week.

“We have someone who’s done this job for 30 years, but they’re retiring. Other team members can’t keep up, and we don’t know what we’ll do when they leave.”

Or, “the cost of local housing makes it impossible for us to hire at entry-level wages.”

Labor Shortage

According to Deloitte, the US is projected to have more than 2 million unfilled manufacturing jobs by 2030. With Vermont’s aging population and housing crisis, we are particularly vulnerable to being left behind.

There is momentum towards re-shoring manufacturing back to the US, and Vermont has a real opportunity to be a part of that. To do so, we must address the structural challenges that make doing business here difficult, while building on the collaborative strengths that make Vermont a supportive place to grow.

Advanced Manufacturing Technology

Technology can be a bridge. Robotics and the Internet of Things help manufacturers do more with fewer people. They reduce injuries, improve retention, and make the work more attractive for younger generations.

But technology alone will not solve the workforce challenge. And even for companies ready to invest in it, Vermont’s infrastructure can create additional barriers.

WalletHub’s 2025 state innovation rankings show Vermont ranks 21st in Human Capital – meaning we have an educated, technical workforce. But our Innovation Environment, which reflects R&D spending, STEM business density, net migration, and infrastructure, ranks just 44th out of 50.

Call to Action

This should be a wake-up call. We’re already at a disadvantage with workforce and modern manufacturing depends on connectivity, technical partnerships, and strong public-private collaboration. We need to invest in infrastructure that helps manufacturers modernize and expand.

One challenge we’ve experienced directly is industrial space. In 2021, when we started looking for a home for Rigorous, we were shocked that industrial vacancy rates in Chittenden County were even lower than the residential market – around 1%. We benefited from the collaborative nature of Vermont businesses, building our first location inside of Vermont Cranberry Company’s newly renovated barn. But after working with brokers and agents and coming up short on our long-term home, we resorted to cold calling property owners to find a suitable fit.

Beyond space, manufacturers face higher energy costs, slow or unreliable internet in rural areas, lack of public transportation, and expansion delays from restrictive zoning and permitting processes.

These obstacles hit growing companies the hardest. We’ve seen Vermont manufacturers move operations out of state once they reach scale – drawn by better infrastucture or outside incentives.

At Rigorous, we are committed to building in Vermont. We believe this is a great place to do meaningful work, and we pay a premium to do so.

I encourage you to value the impact that manufacturing companies have on Vermont’s economy, identity, and community. And to consider policies or incentives to help Vermont companies stay, grow, and thrive here. Thank you again for your time and interest in Vermont’s manufacturing future. I welcome your questions.

U.S. Bureau of Labor Statistics, All Employees: Manufacturing in Vermont [VTMFGN], retrieved from FRED, Federal Reserve Bank of St. Louis; https://fred.stlouisfed.org/series/VTMFGN, April 1, 2025.