Presentation provided at the AICC Annual Meeting on October 7th, 2025. View full presentation here.

Rigorous and the AICC

When Rigorous joined the AICC, the Independent Packaging Association, in 2023, we had just completed our first product launch into the corrugated box market. Our team immediately connected with the independent spirit of the organization and found inspiration in the multi-generational family businesses that define this industry. As a young company, we look up to companies that have successfully passed the torch and evolved through each generation.

Over the past two years, the AICC’s focus on emerging technologies like artificial intelligence has provided a valuable framework for discussing the current state of technology in box manufacturing facilities. As a young company built around modern technology, we’ve learned an essential truth: any increase in flexibility must never compromise reliability. When downtime costs $15,000 per hour per line in lost revenues, box makers need solutions that reduce risk rather than add to it.

The Technology Gap in Box Manufacturing

One conversation from last year’s AI Xperience breakfast stays with me. A box plant owner described feeling a step behind other industries in technology adoption but was uncertain about taking that first step. He compared it to standing with one foot on the dock and one foot on the boat: unable to make a dramatic change from what’s working without more confidence in the destination.

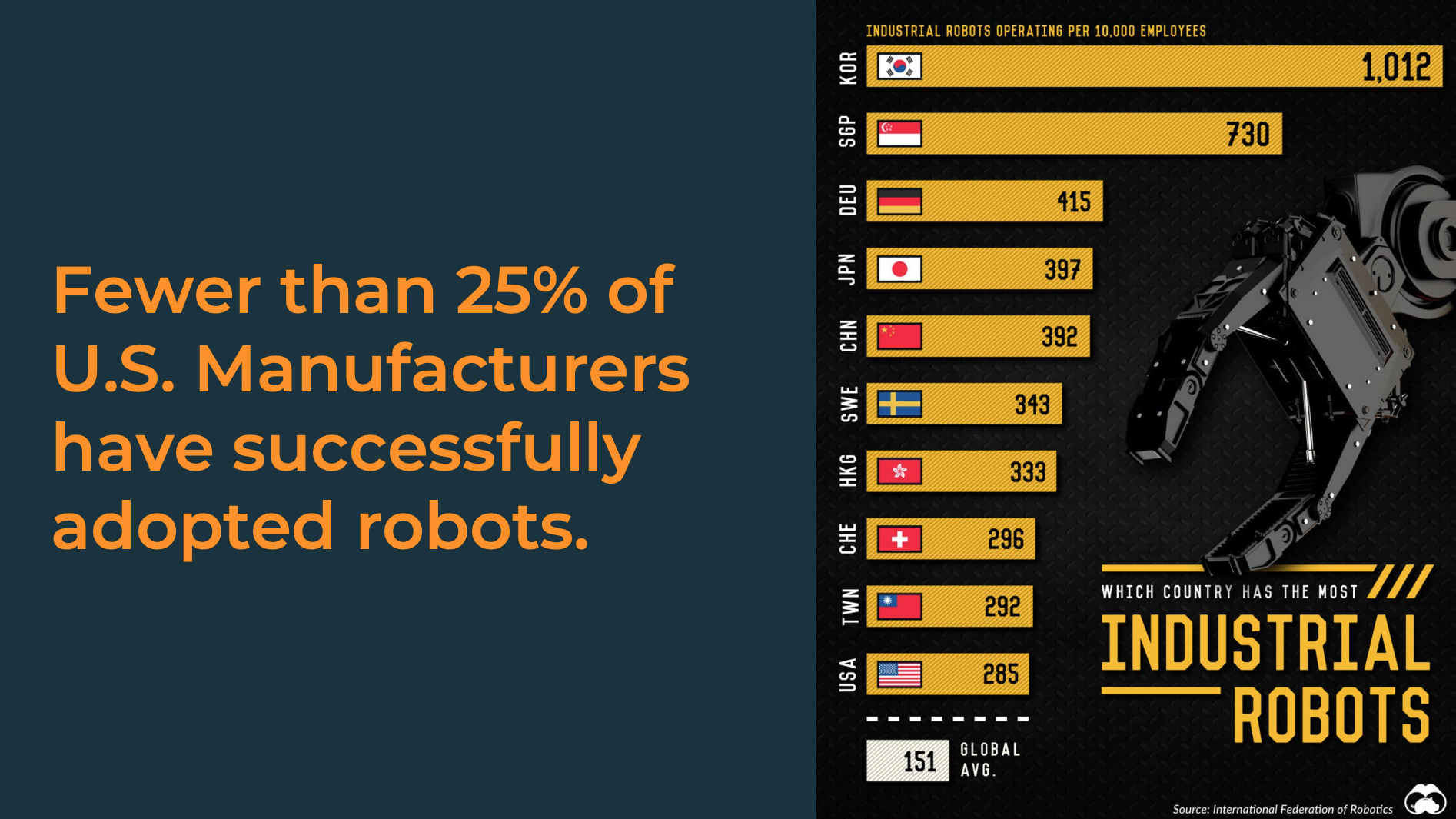

The data confirms this isn’t an isolated feeling. Research shows that fewer than 25% of US manufacturers have implemented successful robotic automation programs. While this percentage is gradually increasing, the number of new annual industrial robotics deployments has actually declined in recent years.

Why Automation Adoption Remains Challenging

The challenge is clear: when operations are running smoothly, introducing complexity and novel technology introduces risk. We believe that for robots to achieve widespread adoption in box plants, they must overcome two critical challenges: flexibility and reliability.

When the AICC invited Rigorous to present on AI innovations at their recent Annual Meeting, I saw an opportunity to discuss not only our newest product launch but also the specific requirements for technology adoption that we’ve identified within the corrugated industry.

As mentioned earlier, we estimate only 25% of US manufacturers have successfully adopted robotics. The United States lags behind key manufacturing nations in Asia and Europe in automation adoption. As efforts to restore manufacturing intensify, we face a critical shortage of personnel. Manufacturing employment has been declining for years, and current projections indicate a 2 million person shortfall by 2030.

While automation can help address this gap, it’s not a silver bullet. For automation to truly support box makers, robots must deliver exceptional flexibility without compromising reliability.

The Reliability-Flexibility Challenge in Industrial Robotics

Industrial robots excel at repeating identical patterns, but modifying them for changing products or layouts can be costly and time-consuming. While robots don’t take sick days or get tired, they do fault. When operators lack the knowledge to quickly recover from faults, they often find ways to work around the robots rather than with them, defeating the purpose of the automation investment.

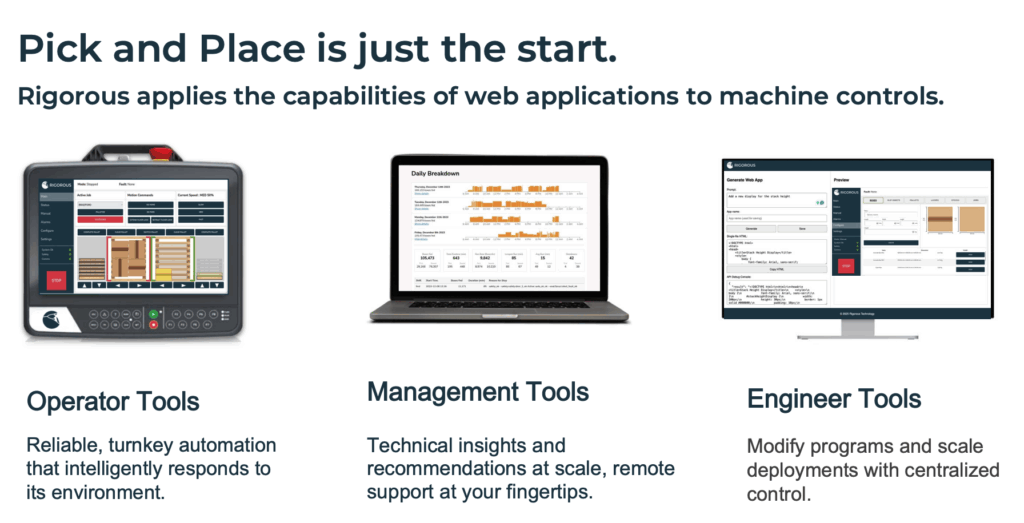

Rigorous was founded in 2020 with a mission to bring the capabilities of modern digital web applications to industrial robotics, creating an improved experience for operators, managers, and maintenance teams.

We’re realistic about the timeline. We’re still at least a decade away from general intelligence machines or “vibe coding” robots. (We’re still waiting for self-driving cars, after all.) However, the field of robotics is advancing rapidly, with new capabilities emerging constantly. At Rigorous, we focus our most advanced software features on applications that meet today’s reliability requirements while building infrastructure for tomorrow’s innovations.

Introducing the RIG Palletizer

This year, we launched the RIG Palletizer to support box makers with intelligent automation. We entered the corrugated industry with a high-speed robotic prefeeder called the Box Hopper. After touring plants nationwide, we identified a significant opportunity for end-of-line automation in finishing departments—along with some unique requirements specific to this industry.

Flexibility Features That Adapt to Your Operations

Unlimited SKUs and Pallet Patterns

Our system offers no-code configuration. Simply enter the product dimensions and pallet layouts, and the RIG handles the robot path planning automatically. No more scheduling technicians to come on-site and write new recipes for each product change.

Mobile Design for Maximum Utilization

Many finishing departments we’ve visited operate 7 specialty folder-gluers but only run 3 or 4 simultaneously. We designed the RIG to be mobile, allowing it to be repositioned where it’s needed most, maximizing your automation investment.

Wide Product Mix Capability

We understand that most products leaving your facility aren’t packed into closed and taped RSC boxes. While most robotic systems are rigid, the RIG offers modular software and tooling to support your full product range. Our tooling accommodates boxes without tops or bottom tape. Our mechanical engineers customize each tool to match your specific product mix, so even bundles are within the system’s capabilities.

Reliability Features That Keep Lines Running

Automated Error Handling

This is where smart software truly proves its value on the production floor. Our sensors validate every pick, and when an anomaly is detected, the system automatically resolves the issue. With most palletizers, if the suction picks up a box incorrectly, it places it down incorrectly—often dropping it or causing it to jam against another box. This requires operator intervention to reposition the box, recover the robot, and clear the fault.

The RIG’s sensors identify incorrect picks and automatically place the box back on the conveyor before attempting another pick. This keeps your lines running and frees operators from constant robot troubleshooting.

Vision-Guided Picking

This feature consistently impresses plant visitors. Our vision systems scan boxes before picking them, eliminating the need for mechanical alignment. You can feed the machine with a standard gravity conveyor, and the system automatically adjusts for misorientation or varied positioning.

After fielding the RIG, we identified an opportunity for enhancement. Now, the vision system also verifies that the box it sees matches the configured specifications, alerting operators to any setup errors or boxes that accidentally entered the wrong line.

The Impact of Smart Software on Box Plant Operations

These features represent practical examples of how intelligent software can significantly improve your operations. By combining flexibility with reliability, automation becomes a true asset rather than another system to manage.

As the packaging industry continues to evolve, partnerships between innovative technology providers and organizations like the AICC will be essential for helping box makers confidently step from the dock onto the boat, knowing their destination is worth the journey.