Standard robots assume standard products. Box plants rarely operate that way.

This content was presented during a recent webinar hosted by Rigorous Technology, “Right Fit Automation in Box Plants”.

As box plants invest in automation, too few see the expected results last over time. In most cases, the gap has little to do with the robot itself and everything to do with how well the solution fits each unique operation. Automation delivers value when it aligns with production realities, workforce needs, and product variability.

That theme framed this webinar, featuring insights from Rigorous’ Colin Riggs, Diane Abruzzini and Chelsea Allen, joined by Tom Fitzgerald of Koenig & Bauer. The discussion explored how automation decisions are made on plant floors, followed by a live demonstration of the RIG palletizer.

What separates automation that lasts from systems that quietly fall out of use?

Koenig & Bauer + Rigorous

The world’s oldest printing press manufacturer, Koenig & Bauer, is a trusted brand across corrugated and folding carton companies, known for delivering the highest performance in print and finishing equipment. As they support their customers on their path to plant modernization, they searched for a robotics partner that was aligned with their ethos of technology excellence and customer-centricity.

As Tom Fitzgerald explained, Koenig & Bauer’s interest in Rigorous was driven by customer experience. Accurate Box Company, an early Rigorous customer, demonstrated what happens when automation is designed around real production constraints.

“They stood out on top from the other competitors we were looking at. Their solutions fit very well, and when you have a very happy customer like Accurate Box, it’s hard not to take a serious look.”

After Rigorous demonstrated an early prototype of the RIG Palletizer, Koenig & Bauer saw the potential to drive significant value to their customers. Both companies focus on innovation, long-term commitment, and systems that perform reliably in real plant conditions.

Closing the Gap Between Machine Capability and Manual Labor

Modern folder gluers, whether corrugated or folding carton, are capable of extraordinary output. In practice, few plants reach those speeds. The limiting factor is rarely the machine itself.

Without automation on both the front end and the back end, the folder gluer’s true capability remains theoretical. Manual feeding and palletizing create physical limits that cannot be sustained shift after shift. As Tom Fitzgerald explained during the webinar:

“Almost every folder gluer, whether on the corrugated side or on the folding carton side, is capable of outproducing anything. Until you can actually really put automation on the front end and the back end of it, you’ll never really utilize your folder gluer. The machine itself is capable of running 60,000 to 70,000 an hour. Without additional automation, you’ll never be able to achieve those speeds.”

Automation is not only about supplementing labor. It is about unlocking the full potential of high-speed equipment plants have already invested in.

Automation, Safety, and Workforce Retention

One of the most overlooked impacts of automation is how it changes the experience of the operators doing the work. When repetitive and physically demanding tasks are removed, the job itself improves.

Plants that automate palletizing consistently report better safety outcomes, stronger retention, and improved morale. Operators shift away from lifting, bending, and stacking and instead focus on quality and keeping production running smoothly. As Colin noted when discussing finishing operators running robotic prefeeding systems:

“Now it’s people’s favorite job. Saying how much better their back is feeling, and how much happy they are running on those machines.”

Defining Success Before Equipment Is Selected

The panel emphasized that automation projects succeed or fail long before a robot arrives on the floor. Colin Riggs shared how his background in underwater robotics shaped Rigorous’ approach. In extreme environments, success depends on understanding how people interact with systems under real conditions.

Rigorous applies that same thinking in manufacturing. Before selecting hardware or software, the team focuses on the Concept of Operations: how operators, maintenance teams, and managers will use the system day to day. That clarity drives decisions around space, speeds, product mix, and changeovers. When success is clearly defined upfront, automation delivers better results.

The Risks of Incomplete Automation

Across the industry, automation often comes close to driving expected outcomes, but not close enough. Systems that automate most, but not all, of the process frequently introduce new upstream or downstream requirements. For example, many robotic systems require consistency of the product. However, in box plants, product is often moved by forklifts or changing its properties due to the changing environment. This can lead a dumb robot to fault as it attempts to handle variable products. When robots fault, struggle with variability, or require specialized intervention, operators adapt by working around them. Over time, those systems stop being used.

Rigorous takes a different approach. Projects begin with proven platforms and apply customization where it matters. Automation is shaped around the operation, not the other way around. Just as important is what happens after installation. Systems that provide visibility into performance, faults, and trends allow plants to continuously improve how they run.

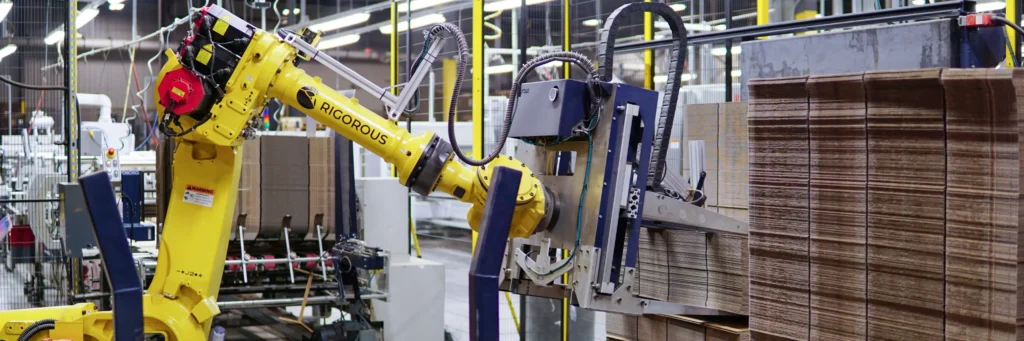

Deployment Example: The RIG in Action

During the webinar, the panel shared a live look at the RIG running at Curtis Packaging. The system was delivered, set up, and palletizing the same day.

The RIG uses a top-pick suction system with end-of-arm tooling matched to each product mix, with optional side-pick support for higher variability. Built on a mobile base with integrated safety scanning, it can roll up to any active line as production shifts. Vision verifies each case before picking, while the safety system creates a 360-degree virtual fence wherever the unit is deployed.

Designing for Real Product Mixes

Standard palletizers assume standard products. Box plants rarely operate that way.

When touring box plants, Rigorous saw a huge need for flexible, end-of-line automation. However, box plants presented some unique requirements to the standard palletizer. Folding carton and corrugated partners are not just moving closed, taped boxes.

End-of-line palletizing often involves untaped boxes, half slotted cartons, bundles, and other non-standard formats. Rather than forcing the product to fit the tool, Rigorous designed an end-of-arm and software solution combining fork support and suction to stabilize open-top cartons, with a pusher ensuring consistent pallet alignment.

When Koenig & Bauer saw the prototype, they recognized the broader relevance. Many plants face the same variability, and solving for that reality is essential.

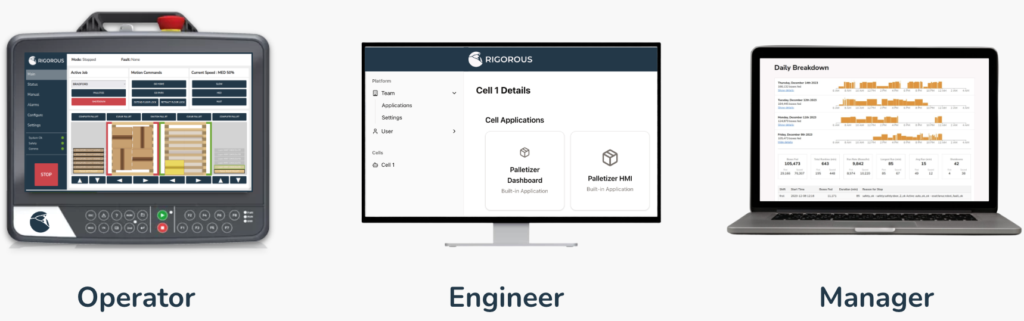

Operator Adoption and Visibility

Ease of use was a consistent theme. Chelsea Allen, our VP of Product emphasized that adoption begins with simplicity:

“I like to say that my mom can use our robots, so they really are built with the operator in mind.”

Operators manage daily tasks through an intuitive HMI, while engineers, maintenance teams, and managers access deeper system views and dashboards. In one example, a failed pick was traced to an incorrect box size configuration in minutes rather than days.

The Most Loved Feature

That same management view also enables Rigorous’ remote support, consistently cited by customers as the most valuable part of the system. Our team can securely log in, see exactly what the plant sees, and resolve issues quickly without waiting for onsite service.

Rigorous can also act as a first line of support for operators, helping people build confidence with the machines and keep production moving.

Conclusion

The session closed with a clear takeaway. Successful automation starts with communication. Sharing product details, production goals, and operational constraints early allows solutions to be designed correctly. When automation fits the operation, supports the people running it, and improves over time, it stops being a risk and becomes a competitive advantage.

Discuss your goals and challenges in a free automation consultation. Click here to talk to our product team.